Mac's Believe It or Not!

by John McDougald

Reprinted from "Crown Jewels of the Wire", March 2002, page 10

The correspondence started innocently enough. Carol got an e-mail from a

collector who had just recently purchased a set of our reference books. The next

line was one we have often heard. "I think I have a piece that's not in

your price guide."

What followed was some information that we had not often

heard. "I would have to say that it has the overall shape of a tall CD 145.

It is 3" in diameter at the base and 4-7/8" high." (Sounded kind

of tall and skinny to me.) "It has an internal petticoat and standard

pinhole threading, extending up the inside of the insulator about 3-1/4"

from the base." (This guy sounds like he knows what he is talking about.)

"There is a vertical slot about 1/2" wide, cut down from the top of

the dome, about 1-3/8" deep, clear through the crown, from one side to the

other on center. In addition, the bottom slot is rotated about 60 degrees

counterclockwise, undercutting the dome. There is also a wire groove about 1/2" wide, approximately 2-1/4" from the base. Are you

interested?"

Well, I didn't do that well in my 7th grade mechanical drawing

class, but something told me that the above description didn't sound like

anything I had ever seen or heard of. I wrote back and asked for pictures.

Initially, my new insulator friend sent CAD drawings. When I got them, I had to

admit that I was a little suspicious. First, the drawings looked like an

insulator from another galaxy. I wondered what was so difficult about just

taking a picture and e-mailing it, but my pen pal assured me that the cad

drawings were accurate.

I asked again if the piece was "glass", and I

was assured that it was. I think I was starting to wear out my welcome with

questions, because I finally got a photo via e-mail that pictured the

"piece" between two CD 145 Hemingray-21's in Hemingray Blue. Sure

enough, it was glass, it was tall, and it looked just like the CAD

drawings. How could something so unusual have escaped the detection of

several thousand avid insulator collectors for so many years? Who manufactured

it? How old is it? Where was it found? More questions than answers.

You've

probably looked ahead to see what I am describing, and I'll bet you are as

amazed as I was. Yes, it's a twist lock style, it's clear glass of high quality,

unembossed, and it's very unusual. The editor and I decided that we really

wanted to see the piece in person. There's nothing like the hands-on test to

make a decision about the legitimacy of a new find. Fortunately, we had planned

to attend the Ann Arbor, MI show in early October, and the "new find"

was not far away.

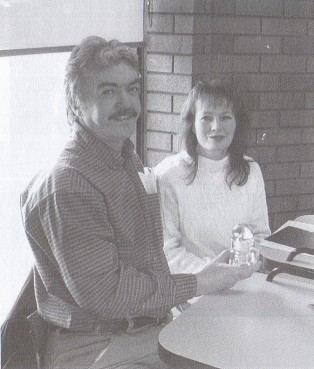

Let me introduce Steve and Linda Wessel from South Woodslee,

Ontario, Canada. After some interesting bantering at the US/Canada border (we

didn't seem to have enough forms of identification to satisfy the customs

agents), we met Steve and Linda at a local coffee shop. We had a very nice

conversation and after about 15 minutes, Steve pulled the piece out of his

pocket. It was everything he had described and more. I really liked it, and

after fondling it for the better part of 30 minutes, we got back to the story about where it had come from.

Steve had picked it up

in a local flea/antique market within the past few months. He paid $5 for it,

and he was quick to remind me that that was $5 Canadian

so that I wouldn't think he paid too much. Unfortunately, as with many of these

kinds of finds, the former owner didn't have any information about its history,

and so for now, we are left to wonder about its past.

We have had the pictures

and drawings reviewed by Elton Gish and N.R. Woodward. Neither have had the

opportunity to inspect the piece in person, so at this time, everyone is just

speculating about the origin of the piece and whether or not it is associated

with any known patents. The two known patents that seem to be closest to the

Wessel's insulator are the Purkey patent from 1914 and the 1940 Sindlinger

patent. Elton also saw some similarities between this piece and the "Cuban

Type" from a 1908 Ohio Brass catalog and similar to U-2015 and U-2019

from Marilyn Albers foreign porcelain book. All of these pieces have been found

in porcelain, but to date, nothing related to any of these patents has turned up

in glass.

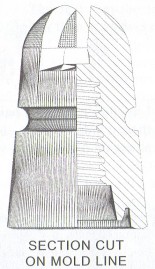

Scale drawing by Elton Gish.

The fact that the insulator is in clear glass also raises more questions than

it answers with respect to the insulator's age. Clear insulators are the

exception rather than the rule for pre-1920 production, but a few have been

found (i.e., CD 141.7 Twiggs Patent), but N.R. Woodward confirms that some clear

glass insulators were made before 1940, "just not many because the

decolorizing process was extra (cost), also a better grade of sand was required

than the cheap, iron-bearing sand used for insulators."

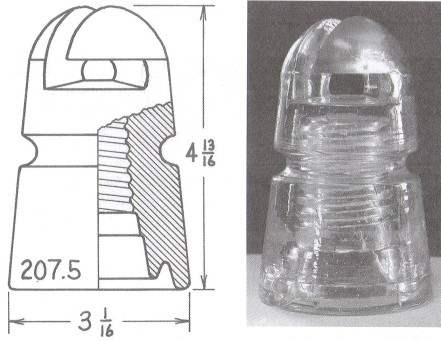

Once Mr. Woodward

had an opportunity to study the drawings and photographs in detail, he assigned

CD 207.5 to the Wessel's great insulator. We are happy to present this new style

to our readers.

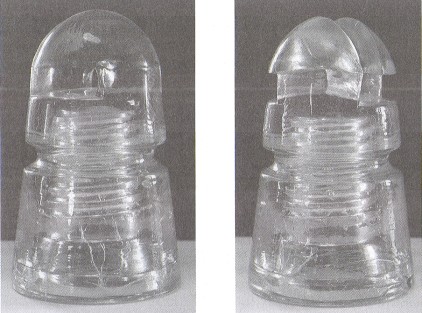

The many "faces" of new CD 207.5, photographed by Steve Wessel.

From owner Steve Wessel: I have verified the requested dimensions as follows:

(as measured vertically from the base with dial calipers)

- Depth of pinhole = 3 - 3/16"

- Start of threads = 1 - 3/16"

- Distance to breakline = 15/16"

- Distance up between petticoat & skirt

= 7/16"

- Distance petticoat is recessed = 3/16"

Please also note that there are radii of approximately 1/8" on the

vertical corners where the line wire enters and exits the crown, under the

overhangs. This is not shown in the preliminary drawing. Please let me know if

you require additional details.

I would like to send along some thoughts on the possible intent of the design

of this piece, only because I design things all day long (mostly automotive

components and assembly equipment), not because I pretend to know anything with

respect to insulators. I have also been thinking about this for quite some time.

So, if you will permit me.....

I believe that whoever designed this insulator,

had the idea that he would improve upon a widely accepted design, currently in

use, namely CD 145. The premise may have been to add a "no-tie"

configuration without substantially changing the current properties of the style.

To do this, the dome area would need to be enlarged, as well as raised

up, to provide adequate glass between the wire and the top of the pinhole.

Basically, the plunger or other device containing the threaded portion of the

mold, would not be inserted as far into the body of the insulator. This would

allow for the same amount of threads, but the sacrifice would be in the reduced

size of the internal petticoat cavity.

I would suggest that the 'long exterior

body' and 'small inner skirt cavity' are features that result from incorporating

the "no-tie" configuration into the dome of a CD 145 style, not intended design features, and thus should not

rule out the possibility that this piece is a communications insulator.

I would

suggest that this insulator design was an attempt to reduce costs on "new

installations" as well as satisfy the "retrofit" market. For

"new installations", the insulator would be threaded tightly onto a

tapered wooden peg. The peg would then be inserted into the crossarm, rotated as

required and pinned in an orientation such that the portion of the bottom of the

saddle groove, under the overhangs, was parallel to the line wire direction.

Lastly, the insulator would be loosened off 1/6th of a turn (60 degrees), the

line wire inserted, and the insulator retightened. If the device which forms the

threads in the mold was fixed in a consistent orientation, with respect to the

dome slot portion of the mold, for each insulator produced, then a broken line

insulator of this type could be replaced with a new one of this same type,

without removing the pin from the crossarm to reorient the slot. The new one

would simply tighten to the same position as the first one.

This principle is

used on a tri-lite light bulb, where the position of the contact for the extra

filament is located with respect to the start of the threads (regardless of the

brand name of the bulb), so that when fully tightened, the additional electrode

in the bottom of the light socket always contacts the corresponding additional

filament contact on the base of the bulb (no matter who the manufacturer is -

i.e. a universal design standard).

This idea would be easy to sell for new

installations and subsequent maintenance cost savings for the same

installations. In the "retrofit" market, the insulator would be used

as a CD 145 style to replace any "side wire" application, with a tie

wire, in a similar manner to the original installation. This is an improvement

over an insulator designed solely to be a "no-tie" product.

I have

also thought about suggestions that this insulator may have been designed for a

specific need in a large industrial establishment. First, there are features on

this insulator that seem to be for exterior use and not needed in an interior

environment. The internal petticoat and the dome-shaped crown for example. Are

these not for shedding water & breaking up a possible leakage path to the

peg, caused by windblown, driving rain?

What about the 1/8" corner radii

mentioned above - are these not to reduce chafing of the line wire due to

constant side-to-side and up-and-down motion caused by the wind? Also, why put a

side wire groove into the design?

Finally, why would anyone design a "no-tie" insulator for such a

specific, limited, low-volume application? The economics are simply not there.

Would there not be a good selection of "tie-wire" types out there that

would suit the application? What kind of quantities would be required -

hundreds, maybe thousands? Hardly enough to justify design, prototypes and

tooling costs (I am quite familiar with this process). As well, any expected

cost savings for such an application would not be realized, as it has been my

experience, in my 25+ years working in industrial establishments, that if I make

a skilled tradesman's job easier to do by reducing the time required to do it,

he will appreciate it, but the end result is not a cost savings at all - you

will just be paying him for an increased amount of idle time!

Even though I

purchased the insulator here in Canada, I would not be too quick to assume that

this insulator is of Canadian origin. I live outside of Windsor, Ontario,

approximately 40 miles. from the Canada/U.S. border and I have traveled at

least an additional 200 miles away from the border into Ontario, in search of

insulators. I would breakdown the spectrum of insulators found over here, from

all sources, as follows:

30% Brookfield

30% Hemingray

30% Dominion (Canadian,

eh?)

10% Whitall Tatum, Pyrex, Armstrong, Diamond, Star & B.T.C.

On the

other hand, there was a glass house by the name of Ontario Glass that operated

out of Kingsville, Ontario (less than 15 minutes from where I purchased the

insulator) from 1898 - 1903 (is this not the time period for the

"no-tie" designs?). Of particular note is the fact that they had a

mold shop in-house there. The chief proprietor was D.A. Gordon of Wallaceburg,

Ontario.- also the location of Sydenham glass and later Dominion Glass. Could

this D.A. Gordon be connected with these glass houses as well?

Further comments from Mac: Having owned the Twiggs Patent, I can only

describe this new find as a "kissin' cousin" of the CD 141.7 Twiggs.

The glass appears to be the same aged crystal clear glass found in the Twiggs

piece. It is a no-tie style and I would be willing to bet it was made in the

same general area surrounding western Lake Erie (whether north or south of the

border) which had many fine glassware houses at the turn-of-the-last century

where such a piece could have been manufactured.

The hobby had the advantage of

having the name TWIGGS and patent date embossed on the CD 141.7 and the related

patent to support the design and application of that insulator when it was found years

ago. Unfortunately, there is no embossing on this insulator, so we don't have

the luxury of being able to state conclusively when, where and by whom it was

made and for what purpose.

Further research may one day reveal the answers to

what can only be speculations at this point. I hope this story encourages you to

keep looking, because Steve Wessel confirmed that he had been in that same shop

dozens of times before without ever finding an insulator worth buying. They're

still out there. Maybe it's your turn next time, Believe It or Not!!

|